Friction Stir Welding of Innovative High Strength Aluminium Alloys

As the world’s second most widely used metal (after iron), aluminium (Al) and its alloys play a crucial role in decarbonizing the transportation sector

and achieving climate neutrality for both the EU and our world. Essentially, Al-alloys reinforced with quasicrystalline (QC) phases have the potential

to be used as the main structural material in e-vehicles due to their strength, lightness, corrosion resistance, recyclability and formability. However,

during the joining process of larger parts, the realised temperature may affect the microstructure and mechanical properties due to the strong flow of

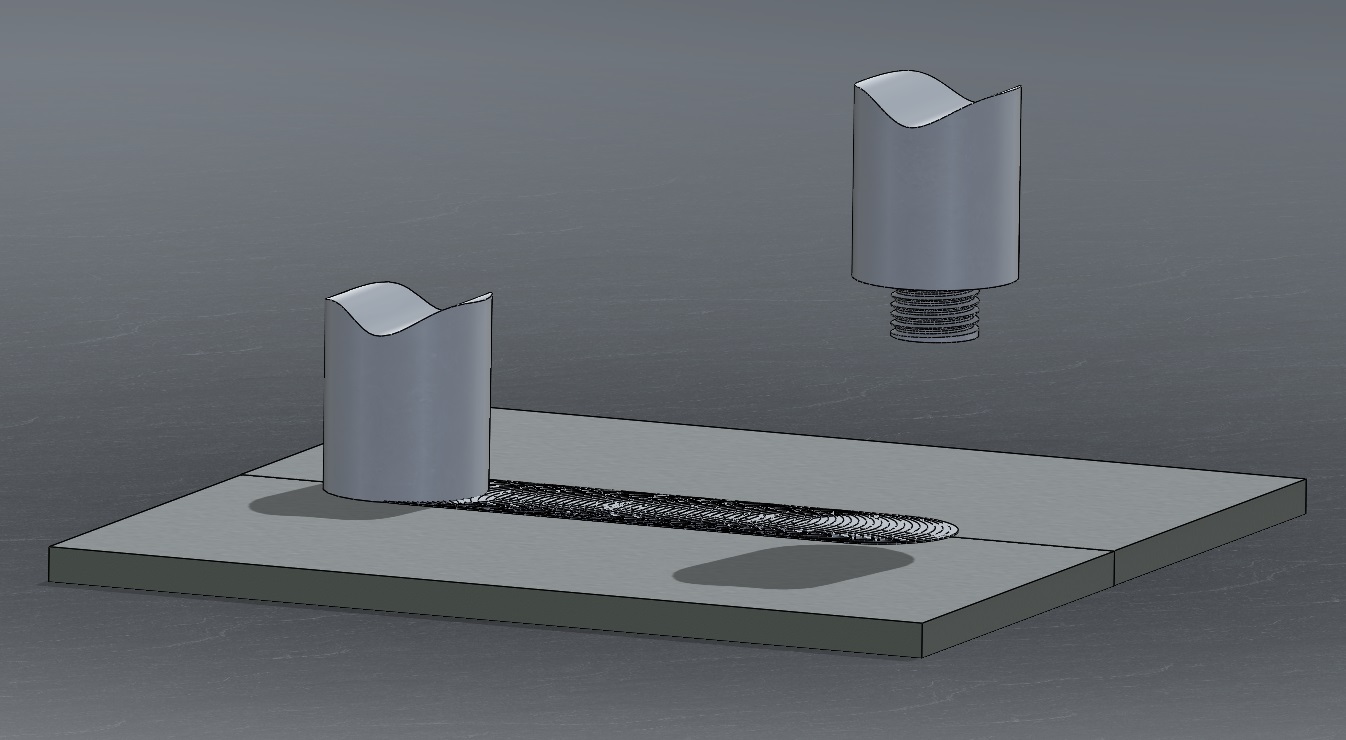

the material and the transformation of intermetallic phases. In this project, the process parameters of friction stir welding will be defined to obtain

high-quality joints.

A passion for creating impact

The successful implementation of the optimized FSW process for high-strength aluminum alloys could revolutionize manufacturing processes and enable the production of lighter and more energy-efficient vehicles. This is in line with the broader societal goals of reducing emissions and improving the sustainability of the transportation sector.

QC alloy

The chemical composition specified in the patent application filed by the University of Ljubljana and Iskra ISD (patent application No. LU503252).

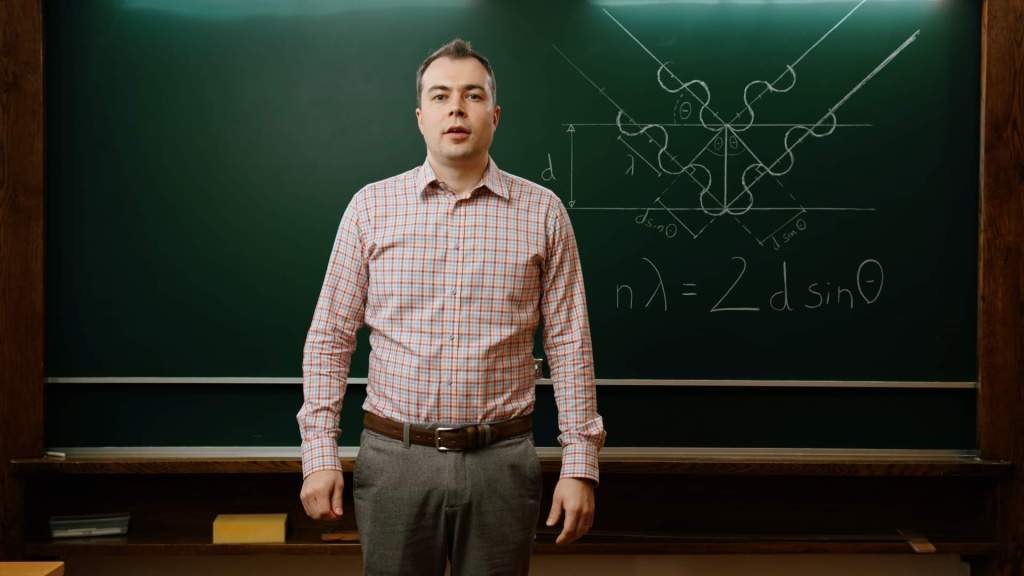

Interdisciplinary approach

The project is closely linked to several research disciplines, such as: Chemistry, Economic Sciences, Information Science and

Engineering and Physics.

Why FSW?

By using the FSW technique, a high-quality joint can be achieved while preserving the quasicrystalline structure.

Scientific impact

Understanding the complex material movement, temperature distribution and plastic deformation of advanced joining solutions for next-generation materials.

Societal impact

The proposed solution, which leads to higher mechanical properties, will have an impact on a better quality of life and a lower environmental impact.

Economic impact

The potential for widespread adoption in key industries suggests a significant contribution to both economic growth and environmental progress.

Knowledge transfer

The interplay between industry, research institutions and academia—drives innovation, economic growth, and societal progress by fostering collaboration, accelerating knowledge transfer, and enhancing workforce preparedness.

ACMiN team

- Structured Mentorship

- Expertise and Training

- Practical Application

- Networking Opportunities

ERA fellow

- Synthesis of complex metallic alloys

- CastQC project

- Case studies

“Unlocking the secrets of metallurgy, harnessing the power of microstructure and pushing the boundaries with quasicrystaline phase – each step brings us closer to engineering materials that redefine strength and innovation.”

Blaž Leskovar

Watch, Read, Listen

Join 900+ subscribers

Stay in the loop with everything you need to know.